As the packaging and advanced materials industry continues to evolve, efficiency, customization, and process stability have become critical factors for manufacturers worldwide. Behind many high-performance protective and cushioning solutions, one piece of equipment plays a decisive role—the EPE profile extrusion machine.

From furniture protection and logistics packaging to sports equipment and architectural applications, EPE foam profiles are widely used across industries. But what makes this machine so essential, and how does it drive innovation in diverse markets? Let’s take a closer look.

An EPE (Expandable Polyethylene) profile extrusion machine is a specialized system designed to produce EPE foam tubes, rods, and customized profiles such as U-shape, V-shape, L-shape, and other complex cross-sections.

Through a continuous extrusion process, the machine delivers:

Stable output and consistent product quality

High flexibility for customized profile designs

Reliable performance for long-term industrial production

This makes it an ideal solution for manufacturers seeking tailor-made foam profiles for protective, insulating, and decorative applications.

The core strength of an EPE profile extrusion machine lies in its interchangeable die head system, which allows manufacturers to adapt quickly to different production requirements.

Depending on capacity and product variety, three configurations are commonly available:

● Single Die Head Extrusion Machine

Designed for mass production of a single profile. It offers high stability, simple operation, and low maintenance costs—perfect for standardized, high-volume output.

● Dual Die Head Extrusion Machine

Enables the simultaneous production of two different profiles, significantly improving equipment utilization and overall productivity.

● Multi Die Head Extrusion Machine

Supports multiple profiles running at the same time, maximizing output efficiency. This configuration is ideal for factories handling diversified or customized orders.

This modular design provides manufacturers with greater production flexibility and faster market response.

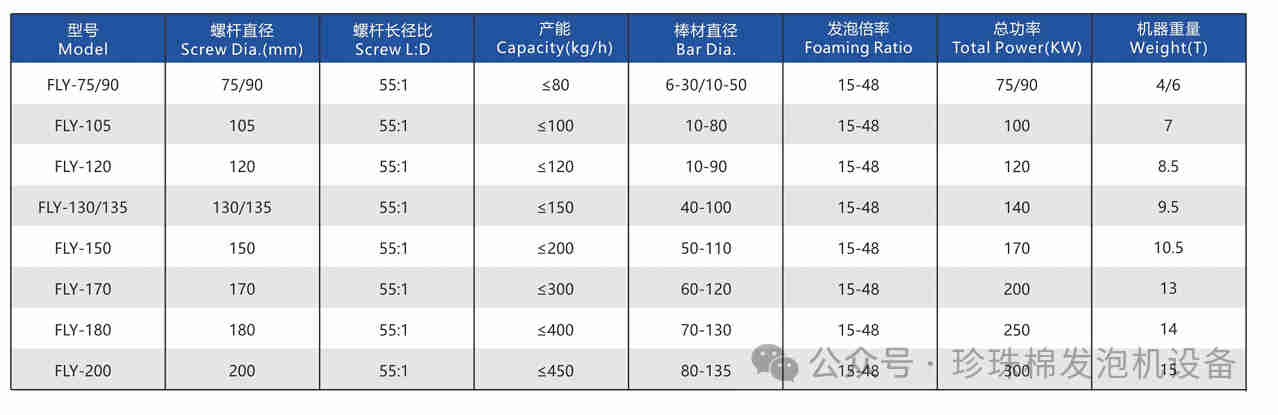

Selecting the right extrusion model is essential for maximizing production efficiency. EPE profile extrusion machines are available in a wide range of sizes, suitable for both small workshops and large-scale factories.

Typical model ranges include:

75 / 90 models – Compact structure, space-saving, ideal for startups or pilot production lines

120 / 135 models – Balanced capacity and stability for continuous industrial production

200–280 models – High-output systems designed for large-scale, long-term manufacturing

When choosing a machine, manufacturers should consider:

Profile dimensions and structural complexity

Required output capacity and production schedule

Factory space, power supply, and auxiliary equipment

Proper selection ensures optimal performance, lower operating costs, and long-term reliability.

As a key piece of equipment in EPE foam processing, the EPE profile extrusion machine has become a true “hidden champion” behind many successful products. Its efficiency, customization capability, and stable operation make it a valuable asset across multiple industries.

Whether your business focuses on packaging, logistics, furniture, construction, or advanced material solutions, a well-designed EPE profile extrusion line can help you enhance product value, expand application possibilities, and stay competitive in a changing market.