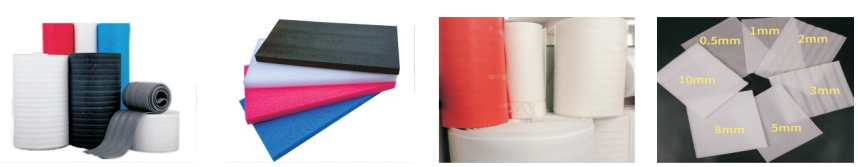

The EPE foam extrusion machine is mainly used for the production of EPE foam. it is made of polyethylene plasticgranule LDPE, which are heated, melted, extruded, catalvzed, and foamed into EPE foam sheets, rods, pipes. y.shaped materials, V profile, fruit net and other plastic materials. The material is characterized by sound insulation, heatinsulation, impact resistance, friction resistance, shock resistance, water resistance, corrosion resistance, moistureresistance, and deformation resistance, and has the characteristics of non-toxic, odorless, and excellent elasticity. Theunique foaming process of Fuliyuan foaming machine can produce 0,35-30mm sheet materials, which can be madeinto various packaging materials and filling materials etc. through bonding and laminating.

Also known as EPE (Expanded Polyethylene), is a versatile material widely used for its lightweight, cushioning, and insulating properties. It is commonly found in packaging to protect fragile goods during transit, as well as in construction for thermal insulation.

EPE foam is environmentally friendly, as it is fully recyclable and biodegradable. Its non-toxic nature makes it safe for use in a variety of applications, including children's toys and medical products. With its growing popularity, the demand for pearl foam continues to rise, reflecting its importance in modern industry.

Huizhou Fuliyuan Machinery Co., Ltd. is recognized as China's leading manufacturer of EPE (Expanded Polyethylene) foaming machines. With a commitment to innovation and quality, Fuliyuan delivers advanced equipment to produce high-quality pearl foam, catering to various industries.